Siemens Drive technology

Converters |

SINAMICS V20 basic converters |

SINAMICS G110 standard converters

SINAMICS G120C compact converters

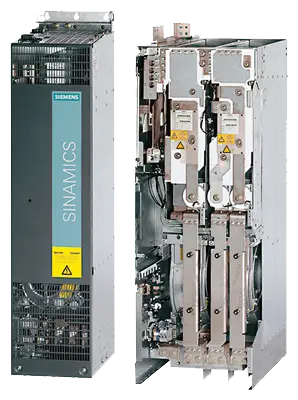

SINAMICS G130 converter built-in units |

The SINAMICS G130 is a converter that can be combined very flexibly with the associated system components and installed into customer-specific control cabinets or directly into machines.

SINAMICS G130 converter built-in units are available for the following voltages and power ratings:

Line voltage | Power |

|---|---|

380 ... 480 V 3 AC | 110 ... 560 kW |

500 ... 600 V 3 AC | 110 ... 560 kW |

660 ... 690 V 3 AC | 75 ... 800 kW |

A wide range of add-on electrical components allow the drive system to be optimized for specific requirements. Configuration and commissioning are greatly simplified by predefined interfaces.

The control accuracy of the sensorless vector control is suitable for most applications, which means that an additional actual speed value encoder is not required.

However, encoder evaluation units are available for the SINAMICS G130 converters so that they can address applications that require an encoder for plant-specific reasons.

Communication between the Control Unit, the Power Module and other active SINAMICS components is performed via DRIVE-CLiQ, the drive's internal interface. The DRIVE-CLiQ connections, which are available as pre-assembled cables of different lengths, allow a complete converter system to be put together quickly.

For communication with the process control system, with the CU320‑2 Control Unit either a PROFIBUS or a PROFINET interface is available as standard. The interface can also be expanded with digital and analog inputs and outputs. The TM31 Terminal Module and TB30 Terminal Board are provided for this purpose. Additional expansion cards can also be installed to allow communication via EtherNet/IP and Modbus TCP.

SINAMICS S220 built-in units

With SINAMICS S120 booksize format, Siemens is one of the world's leading suppliers of drive solutions for machine tools/production machines and General Motion Control applications. Used in a wide variety of areas, industries and applications, Siemens delivers outstanding customer benefits and industry know-how with SINAMICS S120.

The requirements that drive solutions need to meet are continually changing and increasing. Machine solutions need to be perfectly tailored to one another, offer the highest level of functionality and quality, while being economic and simple to implement across the board.

With SINAMICS S220 booksize format, Siemens is enhancing the proven SINAMICS S120 series with considerably more powerful functions and exceptionally compact modules and is providing answers to future requirements. SINAMICS S220 is the reliable, robust, and innovative high-performance solution that meets all the requirements for IoT and industrial security.

SINAMICS S220 Smart Line Modules and Motor Modules are the first steps in innovating the proven SINAMICS S120 range.

Smart Line Modules and Motor Modules are an integral part of the SINAMICS S220 in booksize format and are characterized by the highest level of performance, maximum flexibility, high degree of user-friendliness and being fit for digitalization. They are available in two versions (C and D type). Their higher power density, greater overload capability, and precise dimensioning mean that economical machine solutions can be implemented.

SINAMICS S220 Motor Modules are distinguished by their extremely compact design. The module width has been reduced by up to 50 %, significantly reducing the space required in the control cabinet and in turn reducing costs. Extra slim Motor Modules are also available and allow users to select the exact modules for their application.

Thanks to their innovative mechanical design, Smart Line Modules and Motor Modules are simple and reliable to install and extremely robust.

Operation of SINAMICS S220 Smart Line Modules and Motor Modules is possible with a CU320-2 Control Unit (as of SINAMICS firmware V5.2 SP3 HF10).

Smart Line Modules can supply energy and return regenerative energy to the supply system. A Braking Module and braking resistor are required only if the drives need to be decelerated in a controlled manner after a power failure (i.e. when energy cannot be recovered to the supply). When a Smart Line Module is used as the infeed, the matching line reactor must be installed. A line filter can be optionally installed in order to ensure compliance with the limits stipulated for Category C2 in EN 61800‑3.

A voltage DC link and an inverter for supplying a motor are integrated in the Motor Module.

A Motor Module (available as a Single Motor Module and Double Motor Module) is a power unit (inverter). It generates a variable voltage with variable frequency from the DC link voltage that feeds the connected motor(s).

Drive dimensioning in the TIA Selection Tool

Application-specific requirements can be determined using drive technology dimensioning in the TIA Selection Tool. This can include motors, gearboxes and converters. The tool supports the configuration and dimensioning of control functions with an open and closed control loop. The technical documentation with features of the technical drive system, as well as a product list for ordering via SiePortal can also be compiled.

SINAMICS S120 Combi

Overview

SINAMICS S120 Combi is a very compact and rugged drive concept tailored for compact turning and milling machines.

SINAMICS S150 Converter Cabinet Units |

SINAMICS S150 converter cabinet units are particularly suitable for all variable-speed single-axis drives with high performance requirements, i.e. drives with:

- High dynamic requirements

- Frequent braking cycles and high braking energy levels

- Four-quadrant operation

SINAMICS S150 offers high-performance speed control with excellent accuracy and a high dynamic response.

The following voltages and power ratings are available:

Lne Voltage

380 ... 480 V 3 AC 110 ... 800 kW

500 ... 690 V 3 AC 75 ... 1200 kW

Degrees of protection are IP20 (standard) and optionally IP21, IP23, IP43 and IP54.

Line and motor-side components as well as additional monitoring devices can be installed in the converter cabinet units.

A wide range of electrical and mechanical components enable the drive system to be optimized individually to suit customer requirements.

SINAMICS S120 Chassis Format Units

Function

Communication with higher-level controller and customer terminal strip

As customer interface to a higher-level control, as standard there is a PROFIBUS or PROFINET communication interface on the Control Unit CU320-2; there are also expansions such as the Terminal Module TM31, the Terminal Board TB30 and modules to communicate via CANopen or EtherNet/IP.

These interfaces can be used to connect the system to the higher-level controller using analog and digital signals, or to connect additional units.

For additional information, please refer to the SINAMICS Low Voltage Engineering Manual.

Open-loop and closed-loop control functions

SINAMICS S120 can use a dynamic, high-precision closed-loop vector control (drive object type VECTOR), or a highly dynamic closed-loop servo control (drive object type SERVO).

Software and protective functions

The software functions available as standard are described below:

Software and protective functions | Description |

|---|---|

Setpoint input | The setpoint can be specified both internally and externally; internally as a fixed setpoint, motorized potentiometer setpoint or jog setpoint, externally via the communications interface or an analog input. The internal fixed setpoint and the motorized potentiometer setpoint can be switched or adjusted via control commands from any interface. |

Motor identification | The automatic motor identification function makes commissioning faster and easier and optimizes closed-loop control of the drive. |

Ramp-function generator | A user-friendly ramp-function generator with separately adjustable ramp-up and ramp-down times, together with adjustable rounding times in the lower and upper speed ranges, allows the drive to be smoothly accelerated and braked. This results in a good speed control response and contributes to the reduction of stress on the mechanical system. The down ramp can be parameterized separately for a quick stop. |

Vdc max controller | The Vdc max controller automatically prevents overvoltages in the DC link, if the set down ramp is too short, for example. This may also extend the set ramp-down time. Note: This function only makes sense for single-axis applications. |

Kinetic buffering (KIP) | For brief line supply failures, the kinetic energy of the rotating drive is used to buffer the DC link and therefore prevents fault trips. The converter remains operational as long as the drive can provide regenerative energy as a result of its motion and the DC link voltage does not drop below the shutdown threshold. When the line supply recovers within this time, the drive is again bumplessly accelerated up to its setpoint speed. |

Automatic restart | The automatic restart switches the drive on again when the power is restored after a power failure, and ramps up to the current speed setpoint. |

Flying restart | The flying restart function allows the converter to be switched to a motor that is still turning. With the voltage sensing capability provided by the optional VSM10, the flying restart time for large induction motors can be significantly reduced because the motor does not need to be de-magnetized. |

Technology controller (PID) | Using the technology controller (PID controller) function module, level or flow controls and complex tension controls can be implemented, for example. The existing D component can act both on the system deviation as well as on the actual value (factory setting). The P, I, and D components are set separately. |

Free function blocks (FFB) | Using the freely programmable function blocks, it is easy to implement logic and arithmetic functions for controlling the SINAMICS drive. The blocks can be programmed at the operator panel or the STARTER commissioning tool. |

Drive Control Chart (DCC) | Drive Control Chart (DCC) is an additional tool for the easy configuration of technological functions for SINAMICS. The block library contains a large selection of control, arithmetic and logic blocks as well as extensive open-loop and closed-loop control functions. The user-friendly DCC editor enables easy graphics-based configuration, allows control loop structures to be clearly represented and provides a high degree of reusability of charts that have already been created. DCC is an add-on for the STARTER commissioning tool (see Tools and engineering). |

SINAMICS Technology Extensions (SINAMICS TEC) | The SINAMICS TEC are configurable functions or Siemens technologies that can be added to extend firmware functions. These extensions are designed to allow implementation of highly complex, application-specific tasks for various sectors - such as storage and retrieval machines. Additional information about Technology Extensions (TEC) is provided in the "Technology functions" section. |

I2t sensing for motor protection | A motor model stored in the converter software calculates the motor temperature based on the current speed and load. More exact measurement of the temperature, which also takes into account the influence of the ambient temperature, is possible by means of direct temperature measurement using Pt100/KTY84 sensors in the motor winding. |

Motor temperature evaluation | Motor protection by evaluating a KTY84, PTC, Pt100 or Pt1000 temperature sensor. When a KTY84 temperature sensor is connected, the limit values can be set for alarm or shutdown. When a PTC thermistor is connected, the system reaction to triggering of the thermistor (alarm or trip) can be defined. |

Motor blocking protection | A blocked motor is detected and protected against thermal overloading by a fault trip. |

Brake control | "Simple brake control" for control of holding brakes: The holding brake is used to secure drives against unwanted motion when deactivated. "Extended brake control" function module for complex brake control, e.g. for motor holding brakes and operational brakes: When braking with a feedback signal, the brake control reacts to the feedback signal contacts of the brake. |

Write protection | Write protection to prevent unintentional changing of the setting parameters (without password function). |

Know-how protection | Know-how protection for encrypting stored data, e.g. to protect configuration know-how, and to protect against changes and duplication (with password function). |

Web server | The web server provides information about the drive unit via its web pages. The web server is accessed using a web browser via unsecured (http) or secured transfer protocol (https). |

Power unit protection

Power unit protection | Description |

|---|---|

Ground fault monitoring at the output | A ground fault at the output is detected by a total current monitor and results in shutdown in grounded systems. |

Electronic short-circuit protection at the output | A short-circuit at the output (e.g. at the converter output terminals, in the motor cable or in the motor terminal box) is detected and the converter shuts down with a "fault". |

Thermal overload protection | An alarm is issued first when the overtemperature threshold responds. If the temperature continues to rise, the unit either shuts down or independently adjusts the pulse frequency or output current so that thermal load is reduced. Once the cause of the fault has been eliminated (e.g. cooling has been improved), the original operating values are automatically resumed. |

SINAMICS S120 Chassis-2 Format Converter Units

With its separate power unit and Control Unit, the SINAMICS S120 drive system can be perfectly adapted to a wide variety of different drive tasks.

The Control Unit is selected according to the number of drives to be controlled and the required performance level, while the power unit must be rated to meet requirements regarding regenerative feedback capability or energy exchange. The connection between the Control Unit and power unit is made very simply using the DRIVE-CLiQ digital system interface.

The following devices are available in chassis-2 format:

Active Infeeds (Active Line Module and Active Interface Module)

Motor Modules

Highlights of the built-in units in chassis-2 format

Compact, innovative mechanical design with reduced footprint

Rated pulse frequency of the Motor Modules 2.5 kHz

Optimized derating

Innovative cooling concept

Condition monitoring

Very easy replacement of the device fans